about us

history and technology

Established over 25 years ago we have a commitment to excellence and precision, VF Engineering focuses on enhancing the power and performance of luxury and exotic vehicles, including brands like Audi, BMW, Lamborghini, and Porsche.

the history

Our founder, Nik Saran, exhibited a passion for automotive performance from an early age. He began by fitting superchargers to Volkswagen VR6s, demonstrating his natural talent and enthusiasm for enhancing vehicle performance. This fervor evolved into a professional pursuit, culminating in the creation of VF Engineering in 1999.

Initially focusing on the Volkswagen market, our innovative supercharger systems quickly gained traction. Recognizing new opportunities within Volkswagen’s sister company, Porsche, we launched the 996 Carrera 3.6 supercharger kit in 2003.

The success of our Porsche programs led to a strategic partnership with Stasis Engineering, resulting in the release of a supercharger program for the first-generation Audi R8 V8—our first official foray into the exotic vehicle segment. As the R8 platform transitioned from the V8 to the V10 engine, we engineered a groundbreaking supercharger system specifically for the V10.

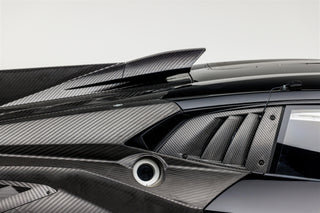

This innovation wasn't limited to just the Audi R8; it was also seamlessly adapted for the Lamborghini Gallardo, which shares the same engine architecture. Our expertise in enhancing V10 performance didn’t stop there. When Audi introduced the successor to the R8 and Lamborghini launched the Huracan, both featuring the advanced V10 engine, our superchargers were among the first aftermarket upgrades available.

This swift adaptation and integration underscored our leadership in V10 performance enhancement, solidifying our reputation as pioneers in the field. Our relentless pursuit of excellence ensures that enthusiasts and professionals alike look to us for cutting-edge solutions in high-performance engineering.

the origins

Complementing our success with precision-engineered and reliable supercharger systems, we launched HEX Tuning in 2015. HEX Tuning offers the highest performance and most reliable engine and transmission tunes for over 200 European and exotic applications.

As demand for our products grew, so did our team and facilities. We now boast a team of over 20 employees and operate out of a state-of-the-art 15,000-square-foot facility equipped with the latest CNC machinery and a cutting-edge dyno cell.

Through dedication and innovation, VF Engineering has gained recognition as a leader in performance tuning, renowned for our superior craftsmanship and unwavering commitment to excellence. Today, VF Engineering stands at the forefront of the industry, continually pushing the boundaries of automotive performance and delivering unparalleled upgrades to discerning drivers worldwide.

technology

At VF Engineering, we blend advanced technology with meticulous craftsmanship to create high-performance automotive parts that set new standards for quality and reliability. Our journey starts with computer-aided design (CAD), allowing our engineers to create detailed 3D models of each part. These digital blueprints help us visualize and refine designs, ensuring they fit perfectly and perform optimally in various vehicles. Next, we use finite element analysis (FEA) to simulate real-world forces and stresses on our components, helping us identify potential weak points and optimize the structural integrity of each part for durability and reliability under extreme conditions. For parts like intercoolers and superchargers, computational fluid dynamics (CFD) allows us to analyze and optimize aerodynamic properties and cooling efficiency. By simulating airflow and heat transfer, we ensure our parts deliver maximum power and reliability.

Precision & Consistency

3D printing is vital in our prototyping process, enabling us to quickly produce and test prototype components for rapid iteration and refinement. Creating physical models from CAD designs helps us assess fitment, functionality, and performance before full-scale production.

CNC (Computer Numerical Control) machining is crucial for producing VF Engineering's performance parts, ensuring exceptional precision and consistency as machines follow precise digital instructions from our CAD models. We use advanced materials, such as aerospace-grade alloys and composites, to enhance performance and durability. These materials are known for their strength, lightness, and resistance to extreme conditions, contributing to the efficiency and longevity of our components.

Before our products reach the market, they undergo rigorous dynamic and static testing. Dynamic testing includes real-world performance trials and dyno tests to evaluate power output and efficiency, while static testing involves stress and heat tests to ensure the components withstand various conditions.

This thorough testing guarantees flawless performance and meets our stringent quality standards. To maximize the benefits of our performance parts, we develop custom tuning software for each specific application, optimizing engine parameters to ensure vehicles equipped with VF Engineering components operate at peak performance. Our tuning solutions result from extensive research and testing, providing precise control over power delivery, efficiency, and responsiveness.

detail & commitment

Our hand inspection and assembly processes infuse each project with care and expertise, ensuring no detail is overlooked. Our quality control protocols are rigorous, encompassing heat and stress testing, real-world driving simulations, and dynamic and static testing, ensuring that every component not only meets but exceeds industry standards, guaranteeing reliability and performance in any environment.

We understand that every vehicle and driver is unique. Our team collaborates closely with customers to develop performance solutions that meet their specific needs and preferences. Whether you seek enhanced power, improved handling, or a complete vehicle transformation, we provide personalized service to bring your vision to life. Our commitment to customers extends beyond the point of sale, offering comprehensive support and aftercare to ensure your vehicle continues to perform at its peak.

Our knowledgeable team is always available to answer questions, provide technical assistance, and guide you in maintaining and maximizing your vehicle's performance. At VF Engineering, our dedication to excellence is embodied in the advanced technology we employ throughout the development and production of our performance parts, ensuring superior performance, reliability, and precision in every product we create.